There are various types of capacitors, but the two main types are electrolytic and ceramic.

Electrolytic capacitors are widely used in circuits where high capacitance is needed, but they are polarity-sensitive, meaning their terminals cannot be connected randomly. In contrast, ceramic capacitors have no polarity, allowing flexible connection, and are generally used for lower capacitance applications.

In this article, we will delve into the world of capacitors and explore the different types available, their characteristics, and their applications.

Capacitor types

A capacitor is an electronic component that stores electric charges.

It consists of two conductive plates separated by an insulating material called the dielectric. These conductive plates are made of metal and are connected to the power supply.

The ability of a capacitor to store charge is measured by its capacitance. The capacitance is denoted by the symbol “C” and measures in Farads (F).

The Farads is a larger unit, so capacitors are typically measured in smaller units such as microfarads (µF), nanofarads (nF), or picofarads (pF).

When a capacitor is connected to a circuit, it can store electrical energy in the form of an electric field. When the voltage across the capacitor changes, it either charges or discharges.

If you want to learn more about capacitor basics check out our detailed article Capacitor Basics, it will help you to understand how capacitors work.

Now what are the various types of capacitors?

There are various types of capacitors, each designed for specific applications and having different characteristics.

Capacitors come in two main types, electrolytic and ceramic types.

Let me explain these two in the following.

1. Electrolytic capacitor

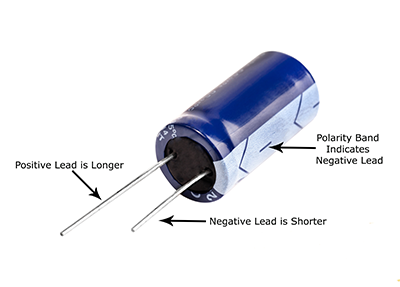

Electrolytic capacitors are mostly used when a larger value of capacitance is required. They are polarized means they have a positive and negative terminal or leg and must be connected with the correct polarity in a circuit.

If the polarity is reversed during connecting this will lead to the permanent failure of the component. Every polarized electrolytic capacitor has a distinct polarity, indicated by a negative sign that indicates the negative terminal, and this polarity must be maintained.

Three components make up an electrolytic capacitor: the electrolyte, the cathode, and the anode. Usually, a small piece of tantalum or aluminum foil serves as the anode, and a conductive substance serves as the cathode.

The electrolyte itself forms a layer of dielectric material that separates the two electrodes. Depending on the particular kind of electrolytic capacitor, the electrolyte may be liquid or solid.

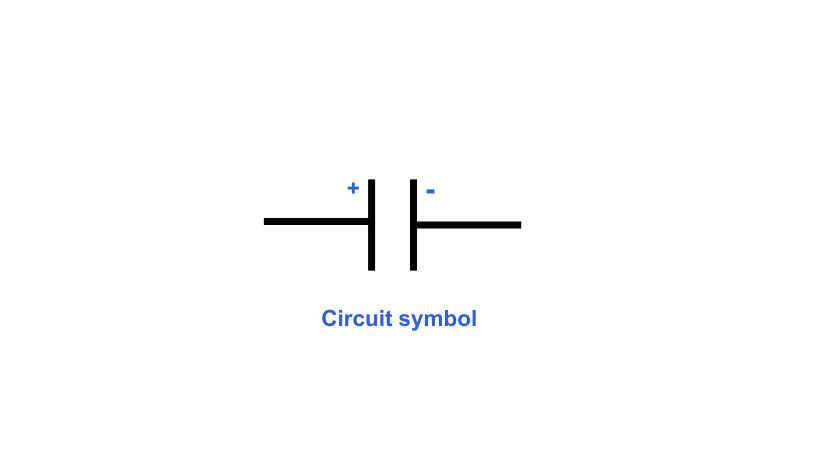

Circuit symbol

The circuit symbol for an electrolytic capacitor includes one straight line (representing the positive terminal) and one curved line (representing the negative terminal), indicating its polarity.

The circuit symbol of an electrolytic capacitor is given below.

Applications

- These types of capacitors are generally used in DC power supply due to their larger capacitance value.

- Their applications can also be found in coupling and decoupling.

- They are also used in audio amplification to reduce electrical noise

Advantages

Here are some benefits of using electrolytic capacitors.

- When compared to other capacitor types, electrolytic capacitors have higher capacitance values. They are therefore appropriate for applications requiring substantial charge storage.

- These capacitors are cost-efficient as compared to other types of high-capacitance capacitors. So for budget-conscious projects, these capacitors are a better option.

- Electrolytic capacitors can provide high capacitance in relatively compact sizes, allowing for space-efficient designs in electronic circuits.

- Electrolytic capacitors are well-suited for low-frequency applications, such as power supply filtering and audio circuits, where their high capacitance values are advantageous.

Disadvantages

Let’s discuss some drawbacks of electrolytic capacitors.

- The electrolytic capacitors are polarity sensitive meaning they have a positive and negative terminal. Incorrect polarity connection can lead to capacitor failure or even damage to the circuit.

- Electrolytic capacitors have low voltage ratings, and exceeding the rated voltage can cause catastrophic failure, including leakage, venting, or even explosion.

2. Ceramic capacitors

When ceramic material is used as a dielectric in capacitors these types of capacitors are called ceramic capacitors.

They are popular in electronic circuits because of their small size, high capacitance value, and good stability.

Ceramic capacitors consist of alternate layers of ceramic material, typically composed of ceramic compositions and metal electrodes.

The ceramic layers act as the dielectric, while the metal layers serve as the capacitor’s terminals. The electrodes are connected to external leads or terminations.

Ceramic capacitors normally have values between 1nF and 1µF, while values as high as 100µF are feasible.

Due to the parasitic effects like resistance and inductance the ceramic capacitors have high frequency response.

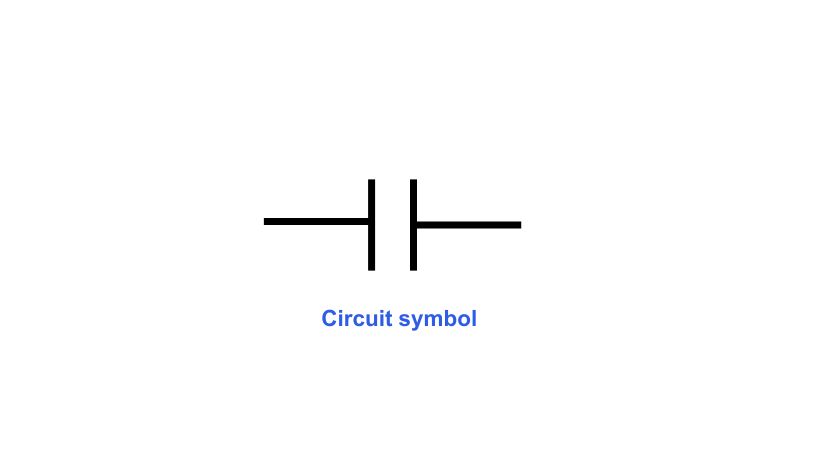

Circuit symbol

The circuit symbol for a ceramic capacitor typically consists of two parallel lines, with each line representing a plate. Circuit symbol helps us to identify capacitors in circuit diagrams.

Here is the circuit symbol of the ceramic capacitor.

Applications

Here are some applications of ceramic capacitor

- Used in printed circuit boards

- Used in DC motors to reduce RF noise

- Used in transmitted stations

Advantages

Here are the advantages of ceramic capacitors.

- The capacitance values of ceramic capacitors vary widely, from picofarads (pF) to microfarads (µF).

- Because of their tiny physical size, ceramic capacitors are well-suited for high-density circuit integration. They are perfect for contemporary electronic products with smaller designs due to their small size.

- Ceramic capacitors come in a variety of voltage ratings, ranging from a few volts to many kilovolts. They can be utilized in high-voltage and low-voltage applications because of their adaptability.

Disadvantages

Let’s talk about the disadvantages of these types of capacitors.

- When subjected to mechanical stress, ceramic materials used in capacitors can exhibit piezoelectric effects, which can generate electrical charges. This phenomenon occasionally causes undesired noise or interference in delicate circuits.

- Ceramic capacitors may exhibit nonlinear capacitance behavior at high voltages or high applied electric fields. This nonlinearity can affect the performance of circuits that rely on linear capacitance characteristics.

Conclusion

A Capacitor is an electronic component used in the circuit to store charges. It is a versatile component with a wide range of types, each catering to specific needs and applications.

Understanding the different types of capacitors and their applications is crucial for selecting the right component to meet specific circuit requirements.

There are different types of capacitors but two main types are electrolytic capacitors and ceramic capacitors.

Electrolytic capacitors are polarity-sensitive capacitors which means you can connect the terminal of the capacitor randomly. They are mostly used in electronic circuits due to their larger capacitance value.

Ceramic capacitors are the types of capacitors that use ceramic material for the dielectric. They are widely used due to their small size and excellent stability.

This was all about the types of capacitors, I hope it will help you to understand the various types.

Thank you and stay blessed…

Other useful posts: