Identifying a faulty capacitor is crucial for troubleshooting electronics, whether you’re dealing with power supplies or other electronic circuits.

There are three simple ways that we can apply to see if the capacitor is a good or bad one. The first method is a visual inspection. The second method is using a capacitance or multimeter to verify its capacitance value with a given tolerance. The last one is by measuring the ESR value of the capacitor.

Some of the above methods are applicable for off and in circuit testing as well.

In the rest of the article, I will talk in detail about the said methods, and much more.

How to tell if a capacitor is bad?

You know, the capacitor is the most used component in almost every electronic and electrical circuit.

The reason why it is so used – they provide us with energy storing and frequency or noise filtering options that are essential to most real world applications.

Like no one wants a noisy device. No one wants a device that is not reliable and its output is not constant.

In short, capacitors play a key role in a circuit. To make sure everything runs smoothly we need to have working capacitors.

But the problem with capacitors is – they degrade as the time passes. You have to replace them.

Sometimes it is really hard to tell if a capacitor is bad or good. Because sometimes even a good looking capacitor is actually a bad capacitor.

So, to make sure we have good capacitors. Following are the easy methods that you can use to tell if you have a bad or good capacitor.

Let’s get started.

Method 1: Visual inspection

This is the easy and most effect way to check for bad capacitors.

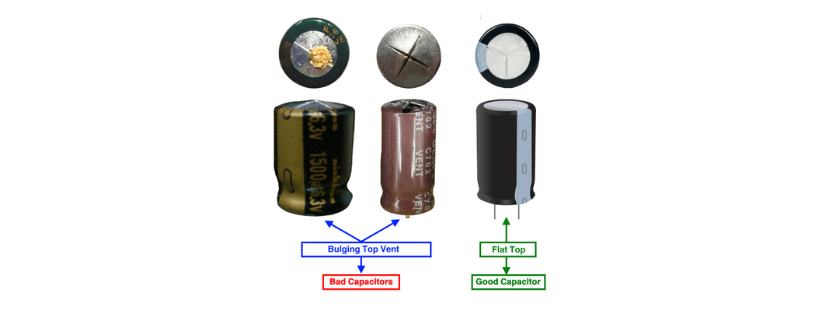

In this method, we look at the under-test capacitor and try to see the following signs:

- Is the body of the capacitor is busted

- Is the top side is popped up

- Is there any leakage on the body

- Is there any bump anywhere on the body of the capacitor

If you see any of the above signs, your capacitor is definitely a bad one, and you must replace it right away.

Method 2: By using capacitance meter

A capacitance meter is an electronics device that measure the value of capacitance for any given capacitor (both electrolytic and ceramic).

Most multimeter also have capacitance measuring feature. You can use such multimeter as well for this method.

Follow the following steps:

- Take your capacitor

- First do the visual inspection. If the given capacitor pass that test. Then try this method.

- Usually a good looking capacitor can be a bad one. You can not filter such capacitor by visual inspection. That is why you should then go for this method

- Discharge your given capacitor by shorting their legs through high resistance material.

- If you forget to discharge the capacitor, this may lead to a false reading and sometimes can damage your measuring device as well.

- After discharging, take the capacitance meter or multimeter and connect the probes.

- Connect the positive probe (red probe) of the multimeter to the positive leg of the electrolytic capacitor and negative probe (black one) to the negative terminal of your capacitor.

- Note the reading on the screen of your device.

Now do the comparison of the noted value to the given value of the capacitor with tolerance.

The given value of a capacitor can be found on the body of it. It is usually written with block letter for easy reading.

Rule is, the noted value must be in the range of 10% of the given value of the capacitor.

For example, the multimeter gives you the capacitance value of let say 9.93F. The given value of the capacitor is 10+/-0.01% F.

Then according to rule. The noted value must be with 10% range of the given value, else your capacitor is bad.

So, the above 9.93 is in range of 10% of 10, i.e. 9-11 range. This capacitor can be considered good.

If you get the noted value of let say 7F, then you would have a bad capacitor.

Method 3: Measuring the ESR value

The above both methods fail to work when you want to test a capacitor in side the circuit board.

Actually, you can use visual inspection method to some extent. But the second method fails totally.

ESR stand for equivalent series resistance. What happens to a bad capacitor is that its ESR value changes. The change in ESR is totally helpful when determining with 100% sure if the capacitor is bad or good.

Usually a bad capacitor can doge the visual inspection method as well the capacitance measurement method. But a bad cap can’t doge this powerful ESR method, especially when it is inside the circuit with bunch of other component connected to it.

To perform this method you need to have a decent value ESR meter. There are many options available on the market. You can search for that.

The ESR meter that I will use for this method is called the MESR-100 (Product link). You can take any meter of your choice; the steps of this method will apply to them as well.

Follow the following step to check if capacitor is bad or good.

- Take the MESR-100 and turn it on.

- Connect the probes

- Short the probes

- And press the zero button – so that you have no prestored value, and you start from zero

- Take your capacitor and discharge it properly through resistance material.

- Discharging a capacitor can be done by shorting the legs of the capacitor by any high resistance substance available to you.

- Connect the discharged capacitor to the ESR meter.

- MESR 100 is an auto range device. It will automatically set the suitable range.

- See the results on the display.

After you take the reading. Compare it to the given ESR table on the body of MESR-100.

If the results match, you have a good capacitor else your capacitor is a bad one.

Conclusion

Capacitors are two terminal passive components that we use for various roles in our circuits.

To make sure we have good capacitors. We need to test and verify them.

In this article, I try my limited knowledge best to share three methods to tell if a capacitor is bad or good.

The first method is visual inspection in which we try to see for some obvious signs on the body of the given capacitor.

In second method, we try to verify the written values of capacitor by measuring it with decent capacitance meter or multimeter.

In the last method, we try to measure the capacitor ESR value and compare it with the given ESR table. This method is also helpful for in circuit caps testing as well.

That’s set. That is all I have for you guys.

I hope you enjoyed it.

Thank you and have a grateful life.

Other useful posts: